Six Sigma is a data-driven methodology and philosophy that aims to improve processes by identifying and eliminating defects or variations that lead to errors or inefficiencies. It is a systematic approach that focuses on achieving near-perfect results by reducing process variation and improving process capability. One of the key principles of Six Sigma is its emphasis on continuous improvement, which is ingrained in its methodologies and practices. In this blog, we’ll explore how Six Sigma drives continuous improvement, its impact on organizational performance, and the role of Six Sigma Course in developing expertise in this methodology.

Table of Contents

- Understanding Six Sigma: A Brief Overview

- Driving Continuous Improvement with Six Sigma

- Impact of Six Sigma on Organizational Performance

- The Role of Six Sigma Courses in Developing Expertise

- Conclusion

Understanding Six Sigma: A Brief Overview

The statistical idea of standard deviation, from which “sigma” is a measure of variance, is whence Six Sigma gets its name. Six Sigma aims to attain a performance level of fewer than 3.4 faults per million chances, or an exceptionally low probability of a defect happening. This performance level is often known as “Six Sigma quality.”

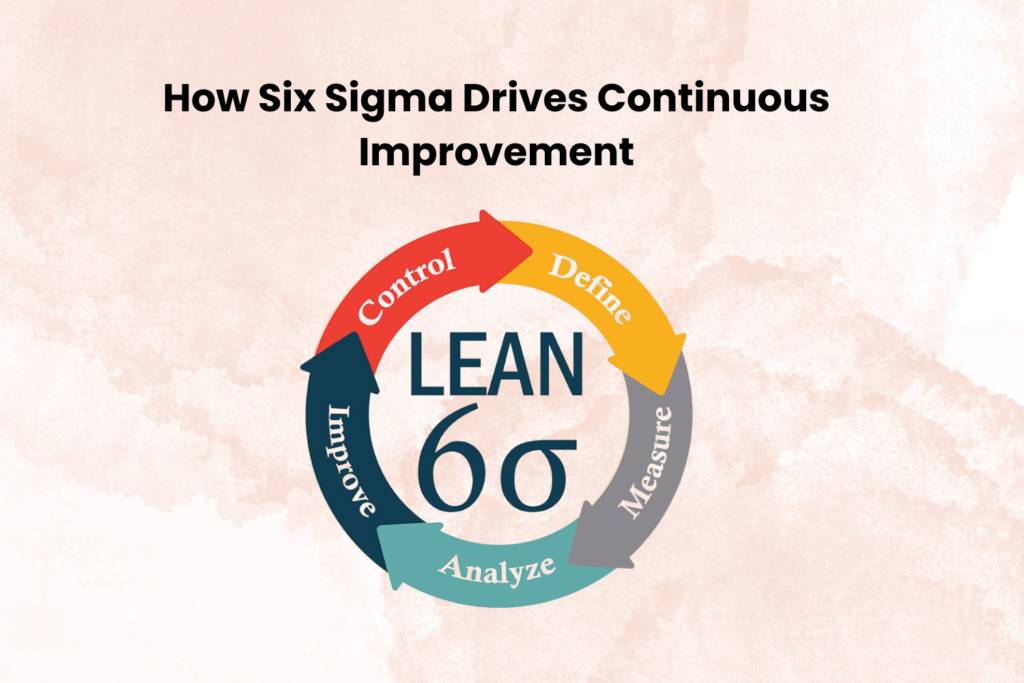

DMAIC (Define, Measure, Analyse, Improve, Control) and DMADV (Define, Measure, Analyse, Design, Verify) are often used in Six Sigma implementation. While DMADV is used to create new processes or products, DMAIC is used to improve existing processes. Both approaches use an organised process that includes gathering and analysing data and putting changes based on statistical analysis into practice.

Driving Continuous Improvement with Six Sigma

A fundamental component of the Six Sigma concept is continuous improvement. Using Six Sigma methodology, organisations may methodically identify areas that need improvement, examine the underlying causes of problems, and implement solutions to promote continuous improvements in performance and processes. This is how Six Sigma promotes ongoing development:

- Data-Driven Decision Making: Six Sigma measures the effects of changes and looks for areas for improvement using data and statistical analysis. Businesses can make well-informed decisions that result in quantifiable process improvements when they use data to guide their decision-making.

- Focus on Root Causes: Six Sigma strongly emphasises finding and resolving issues at their source instead of just managing their symptoms. Organisations can make more long-lasting, sustainable gains by addressing fundamental problems.

- Standardization of Processes: Six Sigma promotes the standardization of processes to reduce variability and improve consistency. Because standardised procedures are simpler to maintain and improve, the results are more reliable and of a better calibre.

- Continuous Monitoring and Control: Six Sigma integrates methods and tools for tracking process performance and putting controls in place to maintain improvements. Over time, organisations may sustain advances by consistently tracking important indicators.

Impact of Six Sigma on Organizational Performance

The adoption of Six Sigma concepts significantly impacts organisational performance. Successful Six Sigma implementations have shown gains in several areas, according to the organisations:

- Quality: Six Sigma reduces mistakes and defects in processes, which increases customer happiness and loyalty and helps organisations reach better quality standards.

- Efficiency: Six Sigma helps companies become more efficient, which lowers costs and improves operational performance by streamlining procedures and cutting waste.

- Innovation: Six Sigma promotes a continuous improvement and innovative culture, encouraging a constant search for methods to better procedures and end products.

The Role of Six Sigma Courses in Developing Expertise

Professionals with extensive knowledge of Six Sigma methodology and tools are essential for organisations to successfully deploy Six Sigma and promote continuous improvement. Six Sigma courses provide thorough instruction on the concepts and procedures of the methodology, giving participants the know-how and abilities required to spearhead projects for organisational change.

Statistical analysis, process improvement techniques, project management, and change management are among the subjects that are often covered in Six Sigma courses. Professionals may improve their credibility and marketability in the job market by obtaining certifications that show their mastery of Six Sigma methodology and concepts by completing Six Sigma courses.

Conclusion

Six Sigma is an effective approach that helps organisations achieve continuous improvement. Six Sigma assists companies in reaching greater standards of quality, efficiency, and innovation by emphasising data-driven decision-making, root cause analysis, process standardisation, and ongoing monitoring. The development of proficiency in this approach is greatly aided by Six Sigma courses, which provide professionals the know-how and abilities required to spearhead fruitful improvement projects and enhance organisational performance.